One of the leading manufacturers and crafters of leather apparels and accessories in India.

One of the leading manufacturers and crafters of leather apparels and accessories in India.

Established in 1996, the company has been providing complete customized manufacturing and OEM solutions to some of the leading brands and fashion houses across the world. Association with such brands assures that quality and environmental standards implemented by Drishti Apparels are approved and recognized by international laws and the fashion fraternity.

See our D&B D-U-N-S Registered Seal here

*The manufacturing process adopted by the company is environment friendly.

Clients

Since its inception Drishti Apparels has always been providing manufacturing solutions to some of the most prominent brands in the fashion industry.

Clients

Since its inception Drishti Apparels has always been providing manufacturing solutions to some of the most prominent brands in the fashion industry.

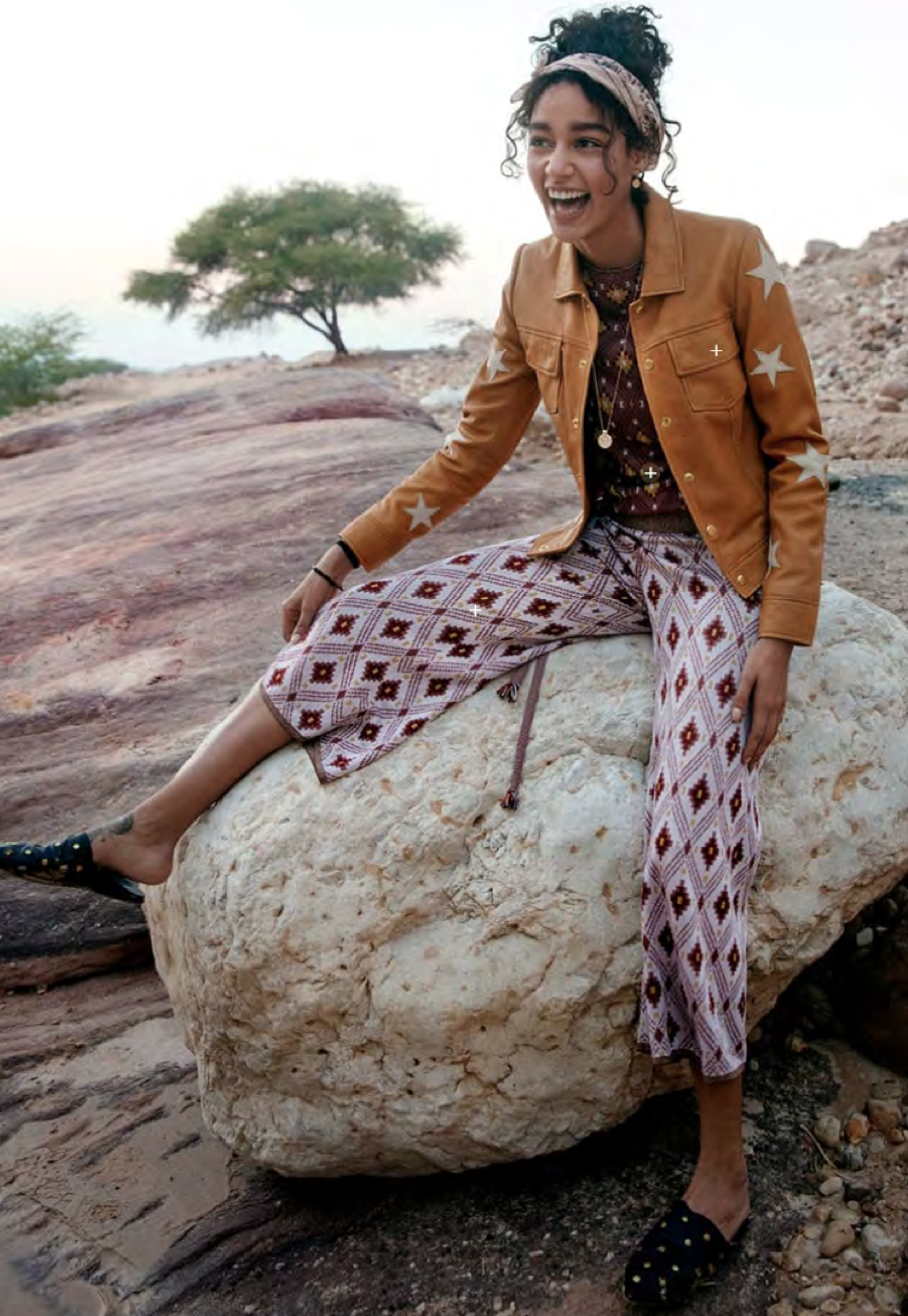

Since its inception Drishti Apparels has always been working with premium brands and fashion houses across the world and has always laid emphasis on timely delivery. Checks are conducted at various stages from leather selection, color matching, leather cutting, stitching, finishing, and packing.

Drishti Apparels has installed needle detection machine to ensure that the articles are free from broken needle parts. All snaps and buttons are checked with pull-test machine as per buyers requirements. Testing of leather/fabric/trims is done to make sure that the final product is of the best possible quality.

Leather Sourcing

Leather Sourcing

Leather forms more than 50% of the cost of the product. The buyers are very quality conscious about the leather. Drishti Apparels has a large network of global sourcing of various types of leathers. For cow, calf, lamb leathers, it has reputed Italian suppliers like ERRECI, MONTEBELLO, SABRINA, MOSTAROTTO. Locally, Drishti Apparels has its own staff based in different cities in India like Chennai/Jalandhar/Calcutta for developments and sourcing.

Drishti Apparels has recently tied up with a few tanneries to work exclusively for production of articles in leather which Drishti Apparels develops from wet-blue stage. We also stocks adequate leather in raw stage (wet-blue) in view of uncertainty in availability of top quality skins.

Sampling And Product Development

Sampling And Product Development

Drishti Apparels is a professionally run organization, laying emphasis on quality, delivery and product development. The company has the capacity and required work force to produce more than a dozen samples everyday, all trims and leather skins are sourced through a network of sourcing personals from across the globe.

The company has a good know how in the areas of embroidery, web stitch, crochet, laser work and printing on leather. The company also has an in-house leather development department which also includes a washing plant.

Infrastructure

Infrastructure

Drishti Apparels has its head office and factory based in Manesar, Gurgaon, Haryana, India. The factory is spread over an area covered over 25,000 sq ft and is 30 kms away from Indira Gandhi International airport.

The factory is equipped with a variety of specialized machineries such as splitting machine, embossing machine, skiving machine, clicking machine, buffing machine, edge coloring machine, coloring/drying machine, polishing machine, stamping machine etc. The company has a workforce of about 250 of which about 80% specialize in different production activities and the rest work towards merchandizing, finance, admin, sourcing, quality control and product development.

The factory has a capacity of producing 9000 to 10,000 leather apparels and 8000 to 9000 leather bags every month. The production is supervised by a team of dedicated and motivated professionals who ensure that the quality and timely production is maintained.